Water in lube oil accumulates during usage

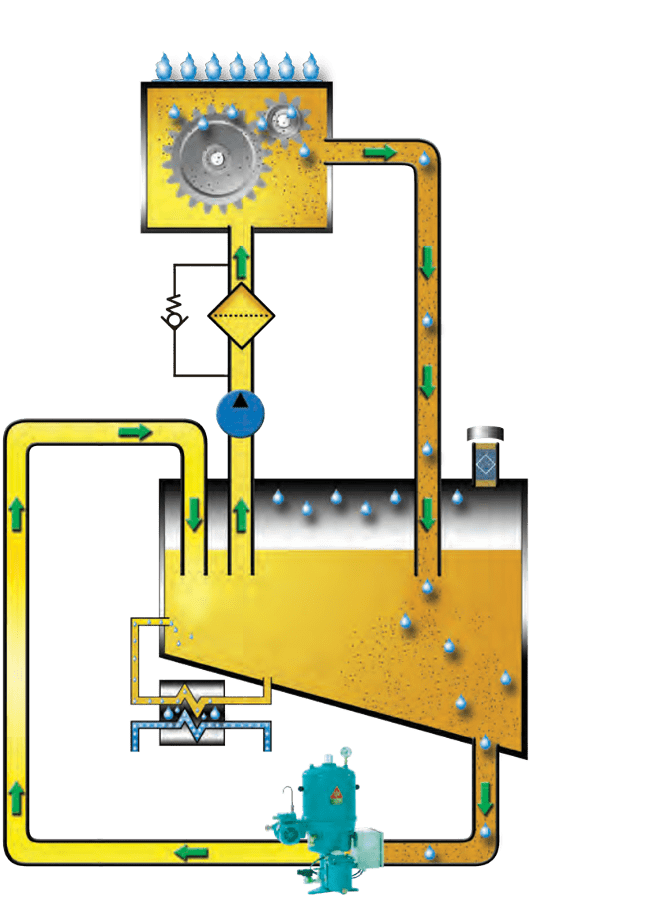

Water in lubrication systems can originate from the environment, such as rain or moisture in the air. Leakage, damaged gasket on reservoir covers, underperforming air breathers, or a damaged wiper on a hydraulic cylinder are also possible sources. Condensation of air in oil reservoirs due to temperature difference between day and night will turn any moisture in the air into water droplets, mixing with the oil. A damaged water-based cooling system in a steam application is another potential water source.

Water in oil can exist in three stages: dissolved, emulsified and free. Below saturation level, the molecules of water are dispersed alongside oil molecules, resulting in water in the oil that is not visible. This is known as dissolved water, the least dangerous water state to a lube system. When the amount of dissolved water exceeds the saturation point, the oil is no longer able to absorb more water molecules, resulting in emulsified water. This is characterised by a hazy or cloudy appearance of the oil.

The effect of water in oil is two fold, destroying both the beneficial physical and chemical properties and characteristics of the oil. This can lead to machine component damage. For optimal protection of machine components the water content should not exceed 30% of the saturation point. Emulsions of water/oil occur mainly due to shear forces in machinery e.g. in pumps, gears and valves.

During equipment operations lubricants are contaminated by wear debris, water and oil residues such as sludge or varnish depending on severity and operating conditions. Kidney loop filtration if employed, can remove these contamination efficiently and economically using absolute filters.